©

NEWSLETTER

Want to know more about the use of Recycled Tyre Materials and Re-Plan activities?

CHECK OUT OUR RECENT MATERIALS HIGHLIGHTING THE KEY FACTS ABOUT:

RECYCLED SBR INFILL MATERIAL

FOR ARTIFICIAL TURF

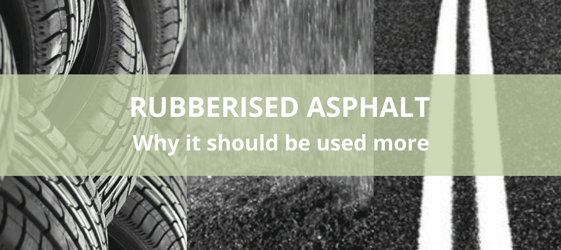

RUBBERISED ASPHALT:

WHY IT SHOULD BE USED MORE

NEWSLETTER 6/2025

KEY EVENTS SHAPING 2025

The 2025 year will be marked by strategic meetings, collaborative projects, staring from WG and SAC Meeting on Rubberized Asphalt on 5 February in Rome and a milestone event — the 30th ETRA Conference on Tire Recycling in Brussels.

This autumn, Re-Plan participated in several important events promoting circular economy and sustainable infrastructure:

- Workshop on RTMs in public works, featuring stakeholder discussions and site visits in Barcelona

- Participation in Pollutec 2024 in Paris, presenting waste recycling innovations and networking with LIFE projects.

- Rubberized asphalt workshop with a technical visit and an international seminar on RTM applications co-organized with LIFE SILENT in Rome

CONNECTING IDEAS, DRIVING CHANGE:

RE-PLAN CITY LIFE'S AUTUMN HIGHLIGHTS

This autumn, the RE-PLAN CITY LIFE project participated in several key events, highlighting its commitment to promoting sustainability, circular economy practices, and innovative approaches to recycling. The season saw dynamic exchanges, networking opportunities, and the presentation of cutting-edge solutions.

One of the focal points was the workshop “RECYCLED MATERIALS and PUBLIC WORKS: HOW TO REDUCE THE GAP” held in Barcelona in November, organized by project partners’ - ITeC - Institut de Tecnologia de la Construcció. It provided a lively forum to analyze obstacles hindering the adoption of recycled materials, particularly in public works, and to present tools designed to overcome these challenges. The workshop put together members of the Stakeholder Advisory Committee and a wide group of experts from the Industry and Public Administration. With participants from eight countries, the discussions were enriched by diverse perspectives, offering a platform for stakeholders to propose strategies, explore synergies with EU programs, and lay the groundwork for future initiatives.

The formula of discussion adopted was particularly engaging. Four groups of discussion were formed, each coordinated by a chairman who collected and ordered the results of the discussion and that at the end summarized and illustrated them to the audience. A series of site visits to Eurofitness Can Dragó Sports Center, EUNCET Business School, Universitat Politècnica de Catalunya further showcased practical applications of recycled rubber, underscoring the tangible benefits of integrating these materials into construction and urban infrastructure. The visit allowed to explain where the Recycled Tyre Material found a suitable application in a sport facility and indeed some of the were visible and directly shown to the group. After the visit there was a meeting with the students to whom some Speakers presented the project and responded to the numerous questions. Later in the month, RE-PLAN CITY LIFE participated in Pollutec 2024 organised by CINEA - European Climate, Infrastructure and Environment Executive Agency. The event also featured pitching sessions and networking opportunities with other LIFE projects, fostering collaboration and the exchange of innovative ideas. Replan took part in one of 4 clusters – Circular economy, which included projects developing actions and strategies for waste recycling and for the reduction of air emission impacting the environment. The session discussed technological measures and capacity building strategies to increase the material recycling and reduce harmful human emissions.

The event was organized in a way to stimulate networking. All the invited projects who took part in the pitch session had the possibility to know each other and talk of possible synergies and cooperation. Then the booth was placed in a strategic position, attracting the attention of the many visitors at Pollutec. The visitors approaching the booth, according to their interest, were introduced by the staff to the project more in line with their request. Roll-up of projects were exposed and materials of project distributed. In December, the first result of the collaboration with the project LIFE SILENT, coordinated by ANAS, was a joint workshop. The workshop was held in Rome titled “Rubber and asphalt mixtures between myth and reality. How to overcome obstacles”, explored the use of recycled tire materials (RTMs) in road infrastructure. Combining technical visits and an international seminar, the event showcased advancements in rubberized asphalt, including innovative solutions to improve durability and reduce costs. The first day was occupied by a visit to an asphalt mix plant who just produced the rubberized asphalt for the LIFE SILENT project and made a demonstration paving in Rome. The visit allowed participants to see how in practice the addition of the rubber powder into the asphalt mix. This plant adopted the so-called dry method, which consists in mixing the rubber powder to then aggregates. On the second day an international seminar with speakers from various countries illustrating each one interesting experiences either from the point of view of the method and technology or the performance. It was possible to know what has been done with rubberised asphalt in Italy, Spain, Poland, Brazil, among the others. One of the key moments of the event has been the Round Table discussion in which valuable Stakeholders took part to analyse the obstacles that limit the use of these materials and how they could be overcome. During the discussion the Round Table the Stakeholders were invited to respond to these points: Which are the obstacles that limit the use of recycled rubber in asphalt ? How could such obstacles be overcome? Which strategies should be adopted to engage Public Administration ? Stakeholders analyzed obstacles limiting RTM adoption and proposed strategies to overcome them, with a particular focus on engaging Public Administrations and promoting Green Procurement. The collaboration between the two projects emphasized the potential for expanding the use of recycled materials and fostering cooperation across EU-funded initiatives. These events collectively underscored the project’s mission to advance sustainable practices and create opportunities for collaboration. By engaging diverse stakeholders, from policymakers to students, the RE-PLAN CITY LIFE project continues to drive awareness and implementation of circular economy solutions, paving the way for a more sustainable future.

KEY EVENTS SHAPING 2025

As 2025 unfolds, the RE-PLAN CITY LIFE project and its partners are set to engage in pivotal discussions and initiatives aimed at advancing the use of Recycled Tyre Materials (RTMs). The year will be marked by strategic meetings, collaborative projects, and a milestone event—the 30th ETRA Conference on Tyre Recycling.

KICKSTARTING THE YEAR: WG AND SAC MEETING ON RUBBERISED ASPHALT ON 5 FEBRUARY

The first key event of the year, the WG and SAC Meeting on Rubberised Asphalt, will take place on 5 February 2025 in Rome at ECOSISTEMI. This meeting builds upon the productive discussions held during the December 2024 workshop, where key stakeholders analyzed the challenges limiting the widespread use of rubberised asphalt.

The meeting will delve deeper into the insights gathered from the previous round table, focusing on:

Identifying feasible solutions for increasing the adoption of rubberised asphalt.

Evaluating strategies to engage Public Administrations in the process.

Exploring the foundation of a new EU-funded project (PAVET) aimed at providing specialized training programs for public and private sector technicians involved in road design and construction.

By bringing together partners from both the RE-PLAN CITY LIFE and LIFE SILENT projects, the meeting will also foster long-term cooperation in sustainable infrastructure solutions. The discussions will shape the next steps toward submitting a project proposal that could significantly contribute to expanding the use of recycled materials in European road networks.

You can also already register!

A LANDMARK EVENT: THE 30TH ETRA CONFERENCE ON TYRE RECYCLING

Another major highlight of 2025 will be the 30th Annual ETRA Conference on Tyre Recycling, scheduled for 25-27 March 2025 at Le Louise Hotel, Brussels. This milestone event celebrates three decades of continuous innovation in tyre recycling, acknowledging the efforts of SMEs, researchers, and policymakers in developing new applications for recycled rubber, steel, and textile fibres.

Over the years, the market for RTMs has evolved unpredictably—some sectors, like sports surfaces, have flourished, while others, such as roads and public works, remain underdeveloped. The conference will explore the reasons behind this uneven growth and discuss strategies for market expansion. A key focus will be on the role of innovation, which remains the driving force for the future of tyre recycling.

The three-day event will include:

RE-PLAN CITY LIFE Workshop, designed to encourage collaboration among Public Administrations and EU-funded projects in the field of RTMs.

Plenary Sessions, addressing pressing industry challenges, including the availability of End-of-Life Tyres (ELT), shifts in the automotive sector, and evolving EU policies. Key discussions will revolve around whether tyre manufacturers can incorporate more recyclates into their production processes and how current legislative changes, such as the new Competitiveness Compass for the EU and how it will shape the industry’s future.

Spotlight on Innovation, where experts will present new technological developments, product applications, and EU-funded research projects that aim to push the boundaries of tyre recycling.

Sessions and Panels, focused on upcycling technologies, such as pyrolysis, and the latest opportunities for funding and cooperation within the EU framework.

Beyond formal discussions, the conference will provide numerous networking opportunities, including cocktail receptions, meals, and informal meetings, allowing stakeholders to exchange ideas and explore new collaborations.

For more information and detailed program visit the website!

DRIVING CHANGE THROUGH COLLABORATION

The events planned for 2025 reflect a shared commitment to overcoming challenges in tyre recycling and fostering sustainable solutions. With key meetings paving the way for new projects and the 30th ETRA Conference offering a platform for industry-wide discussions, the coming year promises to be a significant step forward in building a more resilient and innovative circular economy.

Preliminarily, we plan the following upcoming events:

RE-PLAN Workshop, Katowice | 1-2 October

RE-PLAN Workshop, Crete | Second half of November

Stay tuned for further updates as we move towards a transformative year in tyre recycling and sustainability!

NEWSLETTER 5/2024

Working Group 1 of Replan attended a fully mobile equipment to recycle end-of-life turf that was presented during an open day by All Sports Recycled on 4th June, right in Casalmaggiore.

We are thrilled to announce the launch of the Replan City Life Platform, a dynamic tool designed to empower connections, share knowledge, and foster partnerships within the recycling community.

The LIFE SILENT project aims to develop sustainable and eco-friendly solutions to mitigate noise emissions from road and rail traffic in complex urban environments.

ETRA and AIMPLAS join forces to organize a lively workshop to explore opportunities to set up new EU funded projects on Tyre, Rubber, and Plastic recycling with a high level of valorization.

One of our partner projects is Life Green Vulcan, which aims at increasing the reuse rate of rubber waste with an innovative and environmentally friendly devulcanisation technology.

In Settimo Torinese, Turin, the G. Sattin Sports Centre has undergone a remarkable transformation. Partnering with Pro Eureka Settimo, RADICI SPORT took on a comprehensive renovation project to revitalize this nearly abandoned sports facility.

Previous editions:

Newsletter 4 Newsletter 3 Newsletter 2 Newsletter 1

INTRODUCING THE REPLAN CITY LIFE PLATFORM

We are thrilled to announce the launch of the Replan City Life Platform, a dynamic tool designed to empower connections, share knowledge, and foster partnerships within the Replan Community.

Whether you're an End-user, Manufacturer, Technician, Recycler, or in anyway interested to these topics, our platform provides the information and networking opportunities you need. Join us to access the marketplace, find prospective cooperation, and be part of the Replan Community dedicated to sustainable practices and circular economy.

Join the Replan City Life Platform today!

Website: https://www.replancity.eu/

TURF RECYCLING INCREASES RUBBER CIRCULARITY

Wedged between the territories of Mantua and Parma, Casalmaggiore is a town in the province of Cremona that has always been well known for its proximity to the Po river and its key position for controlling river traffic. Its special connection with the river and its traffic has always characterized the history of this town.

This feature could have contributed to stimulating a team of entrepreneurs to develop and build fully mobile equipment to recycle end-of-life turf that was presented during an open day organized by All Sports Recycled on 4th June, right in Casalmaggiore.

It is a unique wet separation technology to clean and separate sand and crumb rubber with a real industrial capacity. All are tightly integrated into a cost-efficient mobile (or fixed) package, with a small footprint. The quality of the output is very good and allows a high level of circularity.

Working Group 1 of Replan attended this interesting event to either keep track of what is going on in the Sport sector or for a networking opportunity. The interesting talks following the demonstration suggested some reflections on the recent infill ban decision.

This technology as well as many other recently developed and arrived on the market made Artificial Turf completely circular and even more sustainable than it was until now.

These features would maximize its potential if the materials were used, as much as possible, directly on site, reducing pollution and the cost of avoidable transports, thanks to the mobile concept of the technology. This is particularly true for the recycled rubber infill material, which keeps its property unchanged for a long period and may be used again and again in the same place.

It’s a pity that the ban will frustrate, in the future, this potential, requiring us to move output materials instead of supporting a zero-kilometer best practice.

This concept, as said, makes Artificial Turf more sustainable and matches well with the adoption of Risk Management Measures to contain microplastics. Together they address these issues well both during and after turf life, and contribute to a stronger CO2 reduction than other solutions.

THE LIFE SILENT PROJECT: SUSTAINABLE INNOVATIONS FOR LONG-LIFE ENVIRONMENTAL NOISE TECHNOLOGIES

The LIFE SILENT project aims to develop sustainable and eco-friendly solutions to mitigate noise emissions from road and rail traffic in complex urban environments. Noise mitigation in such settings generally excludes the use of solutions that might interfere with the urban context, such as noise barriers, for several reasons.

Firstly, the proximity of receivers to the noise source. Secondly, the visual impact. Noise barriers reduce the visibility of the surrounding environment and hinder air circulation, leading to increased local temperatures (especially in summer) and discomfort for residents. For this reason, the main stakeholders, primarily the European Commission, recommend the use of noise mitigation measures that act directly at the source, such as low-noise pavements. However, despite repeated attempts and various experiments, some of these solutions have proven to be ineffective over time and rather costly.

In this project, the issue of source-based solutions is revisited in an innovative way, through the development and implementation of newly designed road pavements and low-height noise barriers (LHNB), along with adequate technical and managerial procedures to provide infrastructure owners and operators with reliable data supporting their widespread use.

In line with the aforementioned premises, the LIFE SILENT project pursues three main objectives:

1. Improve the durability of low-noise pavements and reduce their cost while maintaining acoustic and safety performance. This objective will be achieved by mixing bitumen with functionalized cellulose fibres from waste materials (e.g., textiles, paper, cardboard) and crumb rubber from end-of-life tyres to enhance the fatigue resistance and the acoustic properties of the road surface. It is estimated that using this technology can increase the durability of pavements by 20% compared to traditional pavements, while maintaining the same acoustic and safety performance. This will reduce long-term costs and improve sustainability.

2. Improve the overall performance of LHNB in terms of acoustic, structural, and safety properties through the design and validation of an innovative product. This objective will be achieved by designing a noise barrier panel, modelled using metamaterial techniques, to achieve enhanced acoustic absorption performance compared to the commonly used fibrous materials, which are known to be less durable. Special attention will also be given to safety and maintenance aspects, as well as the sustainability of the product, by using a high percentage of recycled material (85% of rubber).

3. Define procedures to manage and implement noise mitigation measures in complex environmental scenarios. This objective will be achieved by developing and testing an operational methodology to support the coordination and implementation of noise mitigation measures of various types and nature, to ensure the integration of planned solutions and the achievement of optimal results, both in terms of effectiveness and efficiency.

Together, these efforts will pave the way for quieter, safer, and more sustainable urban environments, showcasing the potential of innovative technologies and recycled materials in addressing the noise challenge.

More info: https://www.stradeanas.it/it/life-silent-en

EXCITING RENOVATION AT G. SATTIN SPORTS CENTRE

IN SETTIMO TORINESE

In Settimo Torinese, Turin, the G. Sattin Sports Centre has undergone a remarkable transformation thanks to RADICI SPORT. Partnering with Pro Eureka Settimo, RADICI SPORT took on a comprehensive renovation project to revitalize this nearly abandoned sports facility.

With the support from Pro Eureka Settimo, RADICI SPORT began by assessing the site's potential and creating an effective plan. In just a few months, they turned the area into a modern sports hub featuring:

Two full-size football pitches (11-a-side)

One 7-a-side football pitch

One 5-a-side football pitch

These new pitches come with fencing and top-quality sports furnishings, ensuring a complete makeover from its previous state of neglect. Every detail of the new pitches was carefully planned and evaluated to meet the needs of a football club aiming for high achievements, especially in nurturing young talent. Two of the pitches are also open to the local community for friendly matches and amateur tournaments.

Artificial turf pitches are often suspected of spilling out of the infill material, spreading microplastics. However, a quality installation and protection system can prevent this inconvenience.

The football pitches were also built including vertical drainage sub-bases, meeting the latest standards set by the Italian National Amateur League (LND) and FIFA Quality Pro Regulation, guaranteeing they remain playable even in bad weather.

Covering 19,000 square meters, the new pitches feature new artificial grass. This state-of-the-art turf, made from special polyethylene fibers, offers high resilience and performance for ball movement and bounce.

The pitches include a high-performance shock-pad, filled with LND-certified silica sand and as infill material recycled SBR green coated granulates, ensuring it meets the standards for matches up to the Serie D category and FIFA Quality Pro certification. They also feature irrigation systems, as required by LND regulations, making them suitable for matches up to the First Category and various youth competitions.

The renovated sports center was officially reopened on May 24, 2024. The celebration included a ribbon-cutting ceremony attended by celebrities from sports, entertainment, and politics, marking the start of a new era for the G. Sattin Sports Centre.

This extensive renovation not only revives a once-neglected facility but also provides a top-notch venue for athletes and the community of Settimo Torinese.

RECYCLING PARTNERS

One of the activities carried out by Replan is networking with other tyre recycling projects to spread information and create cooperation opportunities. Even very different projects can find common ground to synergize, such as joining forces to integrate isolated experiences, materials, and products developed from recycled tyre materials (RTM) into a larger, consolidated European market.

One of our partner projects is Life Green Vulcan, which aims at increasing the reuse rate of rubber waste with innovative and environmentally friendly devulcanisation technology.

In the Life Green Vulcan project, thanks to the innovative technology of Rubber Conversion, it was possible to demonstrate the use of recycled rubber for industrial applications with high technical content. In particular, Stellantis has industrialized a spring support containing 20% recycled rubber and Bridgestone has industrialized a tread for a car tire (PCR) containing 10% recycled rubber by weight.

This result paves the way for the use of high quality recycled rubber for many industrial applications, allowing significant savings in virgin rubber and in particular natural rubber, in full alignment with the EUDR directive (The European Union Deforestation Regulation), and a significant reduction in CO2 emissions. The results of this project served to provide the basis for the proposals for the revision of some important product regulations at the national and European levels, and in particular for the proposal for the revision of the ELV (End of Life Vehicles) Directive.

Website: https://innovandotech.com/innovazione/life-green-vulcan/

WORKSHOP IN VALENCIA "PLASTIC, RUBBER & RECYCLING"

Workshop PLASTIC, RUBBER & RECYCLING will take place in Valencia 1-2 October 2024.

ETRA and AIMPLAS join forces to organize a lively workshop to explore opportunities to set up new EU funded projects on Tyre, Rubber, and Plastic recycling with a high level of valorization.

The event is in presence only and it is designed to offer a strong interaction among organizers and participants.

The key elements are:

- Face to face Pitch Sessions between each participant and experts to discuss your project idea

- Onsite visit to AIMPLAS labs to discover the equipment and facilities that can be used in your project

- Overview and meeting with the team of some successful projects

- Networking Spaces for meetings among Participants and Organizers

- One Day Seminar on most recent R&D Technologies, Market Trends, Cooperation programs, 2025 Calls for EU Projects and other funding opportunities

More info and registration at: https://lnkd.in/d6f9qSfH

NEWSLETTER 4/2024

As part of the the 29th ETRA Conference, an engaging RE-PLAN workshop took place, fostering lively discussions, moderated by Sabina Nicolella from Fondazione Ecosistemi and José Lucas from ITEC.

Rubberised asphalts are technically viable and more sustainable. Demonstration works have been done confirming the feasibility and the benefits. However this application is not well spread and implemented.

In a WORLD CAFÉ dedicated to RTMs we will discuss with Regions and Metropolitan Cities to identify policy tools that allow their greater use in cities as part of the BUYGREEN forum.

SCROLL DOWN TO READ MORE

1

REPLAN WORKSHOP "RECYCLED MATERIALS AND PUBLIC WORKS:

HOW TO REDUCE THE GAP"

In April, the Replan workshop "Recycled Materials and Public Works: How to Reduce the Gap" took place in Brussels as part of the 29th ETRA Conference on tyre recycling. It provided a dynamic platform for engaging in lively discussions, sharing insights, and deepening our understanding of the current situation in the tire recycling sector.

With over 50 enthusiastic specialists from diverse companies and backgrounds, the interactive discussion, moderated by Sabina Nicolella from Fondazione Ecosistemi and José Lucas from ITEC, facilitated meaningful exchanges. The workshop comprised two parts: initially, attendees were invited to a separate room for an interactive discussion moderated by Sabina. Participants tackled important and contentious issues related to the use of recycled materials, drawing from their varied experiences. Towards the end, participants were invited to take sides on the question "Are businesses the main drivers of innovative applications of recycled tyre materials in construction and works?" This proved to be a thought-provoking question, with opinions split and some finding themselves in the middle. Indeed, the question of what and who drives the development of innovative applications is complex.

Businesses often possess the resources and expertise to research and develop new applications, leveraging their knowledge of construction processes and materials engineering. Moreover, they are motivated by economic incentives, as using recycled tire materials can lead to cost savings. However, businesses may also face resistance from stakeholders or consumers skeptical about recycled materials, necessitating education and outreach efforts to foster trust and acceptance. While businesses play a crucial role in innovation, they are not solely responsible for implementing these materials in construction.

The workshop's second part delved into insights on current sustainability requirements for tire recycling materials from Jose Lucas & Tatiana Quintero from ITEC. They shed light on evolving regulations and directives, emphasizing the need for stakeholders to stay informed about forthcoming changes. Documents like user manuals and regulations were discussed to underscore their impact on the market and industry practices.

One key document highlighted was Regulation (EU) 2020/852, which sets criteria for determining whether an investment is sustainable. This taxonomy aims to guide investors, companies, and project designers towards a low-carbon economy and efficient resource use. This reinforces the notion that while the use of recycled materials may currently be a matter of preference for businesses, it will likely become ubiquitous over time.

During the workshop, participants shared insights on how businesses perceive innovations and envision collective solutions for existing challenges. We greatly value face-to-face interactions and the contributions of individuals who openly share their experiences and insights, forming the backbone of our community and driving the advancement of circular economy with recycled tire materials.

2

RUBBERISED ASPHALT: THE SUSTAINABLE WAY

Rubberised asphalts are technically viable and more sustainable. Experiences and demonstration works have been done in many countries confirming the feasibility and the benefits. However this application is not well spread and implemented as it should be owing to a lot of resistances and obstacles.

212.5 million tonnes of all asphalt mixes are produced In the EU-27 (data 2022 E.A.P.A.), so they can be used from 531.125 to 2.122.000 Tons of Rubber Powder

The RE-PLAN CITY LIFE project aims to raise awareness about the Circular Economy opportunities for Materials, Products and applications obtained from tyre recycling to adopt environmentally friendly behavior and practice in urban communities. Promote the use of Rubberised Asphalt is one of the commitments of the project.

During the last ETRA Conference a panel was held on the use of recycled rubber in bitumen and asphalt.

Many things are already known, as the first application dates back to the 50’s - in the USA - and despite continuing since then and the successfully increased performance, in Europe we are still struggling to go beyond to demonstration works. Nonetheless these works started in the 80’s and allowed to develop also in Europe technical skills in various countries.

There are many interpretations and justification that have been formulated on this point. One has been described as “Man in a White Suit Syndrome” in an article published on 26 April 2024 on Tyre and Rubber Recycling.

Difficult to say how much this logic contributes to refusing or slowing down such usage. There are many points that seems to support also different conclusions: The Asphalt Market dimension The EU Government investments The EU Policy on greener and smarter mobility 1. The Asphalt Market is a huge market which could absorb large quantities of recycled rubber:

1 Ton of Asphalt mix contains about 5% of binder = 50 kg bitumen In WET Method we can use (mix) 5-20% rubber powder in the binder (between 2,5 to up 10 kg of rubber powder per ton of asphalt mix)

These data show that even a minor addition of rubber powder in the road asphalt in just the 10% of the EU asphalt market would allow recycling of 10% of the annual European post consumer tyre arising.

2. In the EU, Governments invest around EUR 112 billion a year in transport. These investments are mostly dedicated to building and maintaining roads. These funds could be used in a more sustainable way, if they would consider the use of rubberized asphalt. Without reducing the total investment the same amount would allow to obtain wider and more effective maintenance of the road infrastructural system. In Europe there are a total of over 120 million road segments, adding up to a total of over 19 million kilometres, covering a total of 53 European countries.

3. The EU is strongly committed to support the transition to a cleaner, greener and smarter mobility in line with the European Green Deal and the Sustainable and Smart Mobility Strategy. The revised TEN-T Regulation should put the transport sector on track to cut its emissions by 90%. It responds to the need to increase connectivity across Europe, to foster the resilience of the transport system, to shift more passengers and freight to the sustainable modes of transport and to focus more on sustainable urban mobility. This should also include more durable, safer and cost effective roads.

For what above rubberized asphalt represents the future for road construction and maintenance. This is why Companies and Research Institutes have been developing new technologies or improving the existing ones. The Conference was the occasion to make the point and discuss these issues and challenges. The panel Innovations in rubberised asphalt was chaired by Ir Costis Keridis, an ETRA VP with extensive use on rubberized asphalt who is also coordinating the WG1 of RE-PLAN CITY LIFE project. Dr. Nilufar Lebasi of European Union Road Federation made a picture of the EU policies on Road infrastructure and future challenges. Then some of the most recent innovations from Brazil, China and Poland were presented: Ir. Luis Henrique Texeira of Cbb Asfaltos from Brazil described the Behaviour of asphalt binders modified with rubber powder. They developed a great experience by paving with rubberized asphalt the main motorways. Ir. Hanbing Wang of Shanghai Jiao Tong University from China presented their application with devulcanised rubber in bitumen. - Ir. Przemyslaw Zaprzalski of RECYKL from Poland presented their technology to use textiles derived from ELT.

3

WORLD CAFÉ DEDICATED TO RTMS

AS A PART OF THE FORUM BUYGREEN

The RE-PLAN CITY LIFE Project stops in Rome. On 16 May 2024 at 11.30 we will participate in FORUM BUYGREEN.

In a WORLD CAFÉ dedicated to Recycled Tyre Materials (RTMs) we will discuss with Regions and Metropolitan Cities to identify policy tools in regional strategies that allow their greater use in Building Constructions, Transport and Sports Infrastructures, as well as in Street Furniture. In addition to ETRA and ECOSISTEMI, there will be the Polytechnic of Turin, the University of Turin, the Metropolitan City of Turin, which are partners of the Replan project and have vast experience in the use of these materials.

Forum Buygreen is the reference event in Europe for public and private Green Procurement policies, projects, goods and services. An international event that annually brings together the main players involved in the dissemination and implementation of sustainable procurement of goods and services and in building the right development models for the ecological transition.

For information and registration : https://www.forumcompraverde.it/visitatori/#visitatori-form

NEWSLETTER 3/2024

On 20-21 March 2024 in Antwerpen, in the beautiful Venue of the Handelsbeurs it was held the 10th interregional cooperation forum “Europe, let’s cooperate!”

The RE-PLAN project was introduced at European Summit of Regions and Cities in Mons, Belgium organised by European Committee of the Regions.

Recent results from the RTMs event, organized by the Region of Crete with the involvement of Keridis. RTM's role in Green Public Procurement and public organizations' involvement in Greece.

SCROLL DOWN TO READ MORE

1

SHINY HAPPY PEOPLE MET IN ANTWERPEN

On 20-21 March 2024 in Antwerpen, in the beautiful Venue of the Handelsbeurs it was held the 10th interregional cooperation forum, titled: “Europe, let’s cooperate!”

The aim of the event, perfectly organized, was to present the cooperation opportunities that Interreg Europe offers, both through co-funding for cooperation projects, as well as the activities and services of the Policy Learning Platform. The event brought together participants representing national, regional and local policymakers and other relevant stakeholders from EU regions, representatives from the European Commission and other European institutions and networks. Over 500 attendees from all across the programme area (36 Countries) attended. The profile of the attendees and the high level of professional skills involved made it a perfect audience for the networking activities of Replan. ETRA attended and took part in several bilateral and networking meetings to spread information about the Replan project and to raise awareness on the use of the Recycled Tyre Materials(RTMs) in many different fields of Public Works. Attending was also important as ‘Europe, let’s cooperate!’ marked the launch of Interreg Europe’s third call for project proposals in the 2021-2027 programming period. This call could offer good opportunities to enhance replicability of Replan through cooperation projects in Europe. In addition, the event celebrated a milestone of Interreg Europe expanding to seven new countries and the programme area growing to cover 36 countries in total. The event also showcased successes and achievements of Interreg Europe and interregional cooperation over the years. Over 50 face to face meetings and conversation were made with motivated high level professionals and new contacts established expanding the Replan network. All of them have been invited to participate in the Replan Workshop In Brussels on 17 April 2024 at 14.00 h. The workshop will be held as part of the 29th ETRA Conference.

2

EUROPEAN SUMMIT OF REGIONS AND CITIES

The RE-PLAN project was introduced at European Summit of Regions and Cities in Mons, Belgium organised by European Committee of the Regions.

On 18-19 March 2024 the event gathered numerous Public Administrations from across Europe, with approximately 2000 attendees. It featured a well-organized exhibition showcasing various EU projects.

On the occasion of the 30th anniversary of the European Committee of the Regions, people gathered to reaffirm the commitment to delivering a stronger, fairer and more resilient Europe. The 10th European Summit of Regions and Cities resulted in a call for:

During the summit, we engaged in over 20 detailed conversations, presenting Replan and exploring potential synergies in the above areas. Many projects aligned with Circular Economy, Urban Transition, and Green Deal objectives were invited to the REPLAN workshop in Brussels on April 17, 2024 h.14.00. as part of the 29th ETRA Conference. We should collaborate across all levels, national, regional, or local levels, to make a tangible difference and achieve mentioned goals.

Ambitious public investments, guided by the principle of economic, social, and territorial cohesion. Renewed commitment to the European Green Deal, focusing on climate neutrality and biodiversity. Policies ensuring equal opportunities and addressing diverse territorial realities. Involvement of local and regional authorities in EU reforms and enlargement processes. Reinforcement of the local and regional dimension of European democracy, with enhanced roles for the European Committee of the Regions and active subsidiarity principles.

3

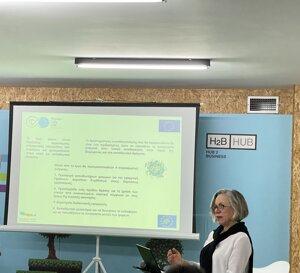

RTMS: BREATH OF SUSTAINABILITY IN OUR CITIES

"RTMs: Breath of Sustainability in our Cities" event was organized by the Region of Crete with the involvement of Keridis Company, Re-Plan City LIFE project partners. On March 27 with 50 attendees including public authorities, academia, and engineers, the event addressed key topics:

- Reevaluating RTMs in Green Public Procurement in Greece through the Minister of Public Works and other Public Bodies

- Post-2031 EU limitations and involvement of Public Organizations

- Technical advantages of Recycled Tyre Materials (RTMs) through networking and dissemination

Attendees discussed the importance of incorporating RTMs into Green Public Procurement practices and shared successful RTM initiatives at both the European and local levels. Moving forward, initiatives will be taken to promote the use of Recycled Tires by agencies.

Thank you to our partners, the Region of Crete, for coordinating and hosting the event!

NEWSLETTER 2/2023

1

RE-PLAN CITY LIFE PROMOTES THE USE OF MATERIALS DERIVED FROM RECYCLED TYRES AT RESTRUCTURA IN TURIN

2

THE EUROPEAN COMMISSION HAS ESTABLISHED THAT FOR THE NEXT TWENTY YEARS IT WILL BE POSSIBLE TO PLAY FOOTBALL ON ARTIFICIAL GRASS PITCHES INFILLED WITH RUBBER GRANULATE OBTAINED FROM TYRE RECYCLING

3

COMMITTEE OF THE REGIONS WORKSHOP FOR

CAMPANIA REGION LOCAL ADMINISTRATORS

The use of materials derived from the recycling of tires in construction was one of the themes of Restructura 2023, the exhibition and conference event held in Pavilion 3 of the Lingotto Fiere in Turin from 23 to 25 November.

Campania is a region in southwestern Italy known for its ancient ruins and dramatic coastline. Naples, the regional capital, is a bustling city with a striking natural setting between the iconic gray cone of Mt. Vesuvius and the deep blue waters of the Golfo di Napoli.

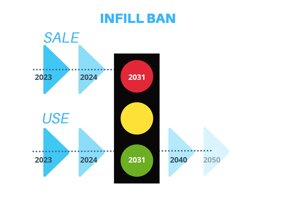

This is what follows from the logical application of the decision adopted on 26 September 2023 to ban the sale (not the use) of polymeric materials for infill, starting from 15 October 2031.

SCROLL DOWN TO READ MORE

RE-PLAN CITY LIFE PROMOTES THE USE OF MATERIALS DERIVED FROM RECYCLED TYRES

AT RESTRUCTURA IN TURIN

The use of materials derived from the recycling of tires in construction was one of the themes of Restructura 2023, the exhibition and conference event held in Pavilion 3 of the Lingotto Fiere in Turin from 23 to 25 November. Re-Plan City Life, the European project co-financed by the Life20 program, intervenes on the topic at the Circular Economy in Construction Conference for environmental sustainability organized by ANTEL (National Association of local authority technicians).

There are many possible uses in construction, for example in concrete, where steel fiber as a replacement for iron bars brings high performance with a considerable reduction in CO2 in the production process. Same thing in the manufacture of acoustic insulation sheaths and much more. The use of materials recycled from rubber also responds to the need to replace elements such as sand and gravel, which are increasingly less available and which are indispensable for cement mortars, with the advantage of contributing to more elastic final products, less subject to fractures.

These materials always guarantee significantly higher performance than traditional ones. However, an innovative effort is needed. In fact, although many technicians are aware of their potential advantages of replacing traditional materials, they often have not had direct experience in using them or sufficient support to introduce them into their projects and programs. Therefore, a crucial element of Replan is precisely to define simple and effective guidelines based on these available experiences, in the context of an implementation strategy.

Geom Bruno Marabotto Vice President of ETRA, European Tire Recycling Association and Prof. Alessandro Fantilli of the Polytechnic of Turin talked about the development of the European project on the use of recycled tires in the construction, infrastructure, and sports sectors, with extraordinary results in terms of economic and qualitative. In fact, excellent quality rubber powder and textile fibers are obtained from tyres, which are used in asphalt, improving drainage capacity and extending their life up to 2 or 3 times compared to traditional ones. They are often used in sports surfaces, such as athletics tracks or tennis courts, and in public areas for children.

The workshops involved also other Speakers with whom there are good synergies who presented other experiences of recycled materials used in the same fields of applications, such as Innovative and eco-sustainable concretes produced from the reuse of waste materials for circular construction, presented by Prof. Dora Foti Deputy Director of the Department of Architecture, Construction and Design (ArCoD). Full Professor of Construction Technology at the Polytechnic of Bari; Woodcircles European Project “Integrated, circular and digitally supported sustainable solutions for waste minimization and carbon storage in buildings and the construction sector, presented by Eng. Laura Ribotta a local Public Administration Official.

The program also included a presentation of GreendealAVR (ARV Climate Positive Circular Communities). The project is working towards the implementation of climate-positive circular communities in Europe, focusing on net zero-emission buildings and neighborhoods. ARV will provide guidelines and a policy framework for future energy-efficient, circular, and digital solutions in the construction industry.

Re-Plan City Life's participation in Restructura 2023 underscored the valuable role of recycled tire materials in construction for environmental sustainability and economic benefits. As the construction industry evolves, the continued integration of recycled materials signals a promising future for sustainable and environmentally conscious building practices.

THE EUROPEAN COMMISSION HAS ESTABLISHED THAT FOR THE NEXT TWENTY YEARS IT WILL BE POSSIBLE TO PLAY

FOOTBALL ON ARTIFICIAL GRASS PITCHES INFILLED WITH RUBBER GRANULATE OBTAINED FROM TYRE RECYCLING

This is what follows from the logical application of the decision adopted on 26 September 2023 to ban the sale (not the use) of polymeric materials for infill, starting from 15 October 2031.

Considering that the average life of an artificial pitch is at least 10-12 years, most of the pitches that will be installed in the next 8 years, for replacing pitches at the end of their life or for new systems, will still be in operation in 2043.

Children born today will be able to play football until they reach adulthood and then they will still have two years, in which as adults they will be able to look around and become aware of the world in which they live and make the choices they deem appropriate.

More information and data relating to the actual release of microplastics from the various sources will be available, while today they have been just estimated and are not always accurate and reliable.

This was not an easy task for ECHA which is often asked to express its opinion on the most disparate issues, from microplastics to the use of certain materials in the space industry. From the infinitely small to the infinitely large.

The microplastic issue is a highly complex one, whose real dimensions, impacts and possible solutions are far from being clarified. It is an infinite topic in itself. The more possible current sources are identified, the more the development of new products and technological innovation can create new ones. At the same time, it is certainly an issue that has a great impact on citizens who, although responsible for the pollution of the planet with their behavior, would still like not to suffer its effects and be able to count on a reduction in any consequent exposure.

Therefore, despite the responsibility of every citizen for the uncontrolled release into the environment every year of 1,000 grams per capita of micro dust (or more precisely nano dust) resulting from the abrasion of tires on asphalt, it is rather blamed the release of 30 grams per capita of 1-2 mm rubber granulates used for infilling artificial grass, which drops to 3 grams thanks to simple containment measures to be applied to the fields as well as more careful and responsible behavior of those who plays on those fields.

It doesn't matter if as a result of the transition to mobility with electric cars there will be an increase in tire consumption and related micro dust emissions, football pitches are pointed out as the main culprits. Since the infinitely small and the infinitely large are difficult to understand, it was chosen to focus on the infinitely medium, either referring to the dimension of particles or to the social context, which are more easily understandable and communicable.

The use of artificial grass pitches is the prerogative of the harassed middle class who do not have access to natural grass pitches, use public transport more and will hardly be able to afford an electric car in the future. Our young athletes don't even use cars and belong to a generation that seems to be able to do without them even when they reach adulthood.

Furthermore, it remains to be seen what the world and mobility will be like in 18 years. They will have greater tools and knowledge to evaluate and compare the overall impact of artificial fields, not only with regards to microplastics, but also CO2 emissions, and other environmental, medical, social indicators deriving from sports practice.

It is probable that they will not agree to give up practicing sports by virtue of decisions, taken before they were born and on the basis of questionable assessments, to combat pollution caused by other sources and other subjects. Not only because it would be serious and unfair, but because sport is now perceived as a right codified in many systems, with different formulations whose meaning can be summarized more or less in the following formulation:

“Sport must be guaranteed to all children and adolescents because it is good for the body, mind and character, promotes socialization by helping to break down barriers between oneself and others, reduces people's selfishness, encourages new friendships and the ability to collaborate, helps to get to know each other”.

In the next few years, a frighteningly high number of football pitches will reach the end of their life and will have to be redone, millions of square meters, which would be logical to redo by recycling as much as possible, directly on site, the materials already used for the construction of the same pitch, and where not suitable or sufficient, use additional materials always coming from recycling chains.

Over twenty years ago, the tire recycling sector contributed to the development of artificial grass pitches, making them high-performance, accessible, sustainable and encouraging their diffusion, to the detriment of virgin materials and more expensive techniques.

Now, due to a heterogeneity of purposes, there is a risk that less sustainable materials will regain space and occupy a market that did not exist, created thanks to recycled materials. Instead of consolidating the principles of the circular economy, we risk to assist to a U-turn in the direction of the linear economy: disposal of old fields instead of re-use and recycling of materials, new fields with lower performance, shorter duration, more expensive materials that require long-distance transport, increased costs and greater CO2 emissions.

What to do?

It must be clear and reiterated that for the next 8 years the fields can and must be made with recycled rubber infill material and that they can remain in regular operation until they reach the end of their life.

Furthermore, rubber granulate is an excellent material for the creation of Elastic Layer which is not affected by the restrictions for microplastics as it is agglomerated with binders. Tire recycling sector is a dynamic and creative sector and is already committed to developing new solutions for both the sports sector and others. It always has and will continue to do so.

In the meantime, it is advisable that these fields be always done with suitable containment measures which have now become good and consolidated practice. This represents not only a clear signal of responsibility and coherence, but a necessary premise for sustainable supply and management over the next 8 years and the subsequent life span of the fields.

We don't know what will happen in the next twenty years, but if the alternatives that the legislation now considers compatible prove to be insufficient or unsuitable, the sector will have the credibility and data in hand to discuss the issue again.

In twenty years the new generations will have a voice to say what world they want to live in and we won't be able to stop it.

COMMITTEE OF THE REGIONS WORKSHOP FOR CAMPANIA REGION LOCAL ADMINISTRATORS

Campania is a region in southwestern Italy known for its ancient ruins and dramatic coastline. Naples, the regional capital, is a bustling city with a striking natural setting between the iconic gray cone of Mt. Vesuvius and the deep blue waters of the Golfo di Napoli. To the south, the Amalfi Coast is home to pastel-hued towns such as Positano, Amalfi and Ravello, nestled between cliffs and the sea.

The Romans knew the region as Campania Felix, which translates into English as “fertile countryside” or “happy countryside” as it was the most fertile area harvesting and supplying food to Rome Empire as well offering attractive holidays locations to Roman Nobleness thanks to the beauty of the places and the mild climate.

Over 50 among Majors, Councillors, and Public Officials coming from Municipalities and local bodies of the Campania Region left for few days their sunny landscapes to come to Brussels to take part to a training event organised by EIPA, European Institute of Public Administration held at the Committee of the Regions from 22 to 24 November.

The event was supported by Brussels Office of Campania Region, who included this event in the frame of a wider training program aiming to stimulate an active use of the EU funding instruments to create opportunities of developments for the rural areas.

The objectives of the workshops and background policies were deeply described by on. Nicola Caputo, Counsellor at Agriculture of the Region and by dott. Nicola Oddati, director of the Region’s Brussels Office, in two separate speeches.

The event, titled “Communication action aimed at disseminating the opportunities of European funds and the activation of exchange paths of good practices”, has been designed to allow a strong interaction between speakers and participants.

The face to face module was Indeed very lively and provided participants with an in-depth analysis of European policies and programs of relevance for the Campania Region in the context of European funds. Alongside European policies and strategies, the module also combines the first experiences from ESF+/EAFRD programming but also from complementarities with direct funds in the fields of training/education and agriculture. The course also includes a direct in-depth study of design methodologies. Speakers from European institutions and interest representatives in Brussels will participate to share good practices.

Ettore Musacchi, Coordinator of RE-PLAN CITY LIFE project took part as speaker to present the project and explain to the audience the many possibilities of using the Recycled Tyre Materials (RTMs) and the other opportunities for local bodies.

This was a perfect context for the Replan project and the presentation raised great attention and a lot of demands which were also addressed during the breaks and networking moments.

It was exciting to see how much motivation and sensitivity to Environment and to Circular Economy principle drive the policy of Local Administrators who were interested to have a future follow up to explore more in detail solutions suitable for their administrations, spanning from Sports Facilities to Roads Constructions.

The training session included:

• Update on European policies in the fields of training, education and social innovation and rural development

• The innovations in the ESF+ compared to the ESF and the EAFRD and the critical points of the European and NGEU/PNRR planning

• In-depth study of design techniques, financial management

• Visit to the European institutions (European Parliament in Brussels, Committee of the Regions, Permanent Representation of Italy to the EU) Course recipients Group of political-administrative level officials of the Campania Region (Agriculture Training Department).

The rich program and the quality of speakers made the event successful not only in providing valuable knowledge but also to open up potential opportunities for future cooperation.

NEWSLETTER 1/2023

1

RE-PLAN PROJECT MEETING IN TURIN: SHARING THE RESULTS OF WORKSHOPS ON RTMS IN BUILDING CONSTRUCTION AND RUBBERIZED ASPHALT

2

INNOVATIVE USE OF RECYCLED MATERIALS IN ROAD PAVEMENTS: A SPOTLIGHT ON THE WARSAW CONFERENCE “MODERN ROAD PAVEMENTS 2023”

3

SUSTAINABLE SOLUTIONS WITH RECYCLED MATERIALS AT THE BUILDING EXHIBITION “SAIE” IN BARI

SCROLL DOWN TO READ MORE

RE-PLAN PROJECT MEETING IN TURIN:

SHARING THE RESULTS OF WORKSHOPS ON RTMS

IN BUILDING CONSTRUCTION AND RUBBERIZED ASPHALT

It's time to share the results of the meeting in Turin, Italy, on September 28th and 29th, 2023. Thirty-four persons from 8 countries attended the Turin Project meeting and the two workshops.

The first day started with the RE-PLAN CITY official project meeting and the Workshop on Rubberised asphalt, which concluded with a fruitful round-table discussion. Participants, including manufacturers and contractors, actively engaged in discussions about current industry challenges and potential solutions.

We were confronted with a question regarding Rubberized Asphalt. What is the actual situation in Europe? Costis Keridis, with extensive experience in road infrastructure, shared his valuable insights. What are the contractors' myths about rubberized asphalt? The primary concerns are the ruining bitumen storage tanks, the necessity of special equipment, and the that the Asphalt mix blend design cannot be varied. These seem to be very simple excuses. However, the reality is different: Plant production reduction by approx.30% or Application cost is similar to other modified mixes (SBS,ECA etc). After considering all available information, we can conclude that the benefits of rubberized asphalt are many and they include reduced thermal cracking, rutting, ice disbonding, and increased aging resistance, flexibility, and raveling. This is only a portion of the complete picture described during the workshop.

On the 29th, during the Recycled Tyre in Building Construction workshop, participants had the opportunity to visit the Concrete Structure Labs. We observed diverse materials, such as recycled steel fibers in concrete, recycled aggregate in concrete, touched recycled steel fibers and recycled textile fibers with our hands. We walked through the entire laboratory and studied in detail the stages and process of testing materials, so we gained a comprehensive understanding of the manufacturing processes.

Following this, a series of presentations and lively discussions took place. The question of whether rubber and concrete can be combined was addressed by Johan Engdahl of Rubber Concrete, who presented compelling possibilities. Many experiments were showcased, revealing considerable experience and innovative products. During the presentation, product samples were provided, allowing attendees to touch and try them for a hands-on experience. Making tires into concrete is a new technology. However, the process, obstacles, and solutions were described in detail during the entire production phase. A significant portion of these applications is designed for horsekeeping, offering ecological and improved conditions for horses.

Steel Fibers and Recycled Aggregates in Concrete mix. Ing. Corrado Barbero from BOTTA described the cautious approach to this process. Manufacturers know there are some difficulties in using recycled products, such as their confrontation and a tendency to stick to the operators' clothing. However, this issue was solved by implementing special equipment, making it possible to distribute the quantity of fibers required for the chosen mixture within the mix. Overcoming these technical difficulties, we can improve concrete characteristics to such an extent that a certain amount of iron's bars that was previously necessary can be eliminated.

We also discussed other topics in the recycled materials sector, such as RTMs in Concrete and Cement-based applications and optimizing tyre rubber-concrete formulations for scaling up to lightweight paving applications.

We want to express our gratitude to all the speakers:

Ing. Marco Benso from Città Metropolitana “Rubberised Asphalt the cautious approach of the Public Administrations and the role to play.”

Sabina Nicolella from Fondazione Ecosistemi “How to overcome the obstacles: the role of Replan project”

Ricardo Ayala from Flexofibers “Recycled steel fibres in on-site applications.”

Prof. Marco Valente, Dr. Matteo Sambucci from La Sapienza University “Optimizing tyre rubber-concrete formulations for scaling-up to lightweight paving applications.”

José Lucas from ITeC “The steps to implement the GPP”

INNOVATIVE USE OF RECYCLED MATERIALS

IN ROAD PAVEMENTS:

A SPOTLIGHT ON THE WARSAW CONFERENCE

“MODERN ROAD PAVEMENTS 2023”

Modern road pavements: latest updates

The RE-PLAN city life project attended a conference on Modern road pavements, and we are ready to share the experience with you. "MODERN ROAD PAVEMENTS - Recycling in road pavement structures" 2023 was held on the 18th of October in Poland, in Warsaw.

The Conference is an excellent opportunity for all manufacturers and professionals in the field of road infrastructure, that's why it was attended by more than 100 participants from industry, Universities, Research Organisations, and Public Bodies. Among the discussed topics were asphalt mixtures with recycled materials, road pavement structures, pavement rehabilitation, and how to make components more ecological.

The application of recycling is highly beneficial in constructing new roads and in repairs and reconstruction. It even helps repurpose waste from other industries. Moreover, recycling can potentially be applied to the subbase and lower and upper pavement structural layers. However, making it happen depends on regulations and technical requirements. Researchers and construction companies must get creative, research, and assess the economic and environmental aspects. That's why disseminating knowledge to all participants in the construction process is the key to success.

Why is recycling becoming a necessity for infrastructure projects in the construction industry? The circular economy forces manufacturers to reduce the consumption of natural resources, and recycling in road construction is a game-changer in this case. It's not only eco-friendly but also a smart way to save materials and energy. The consumption of materials (e.g., aggregates) is significant, and the production, transportation, and construction processes require a lot of energy.

RE-PLAN CITY LIFE project aims to raise awareness about the Circular Economy opportunities for tyre recycling materials on roads, especially in rubberised asphalts. That's why ETRA was kindly invited to attend, make a presentation, and share many years of experience with the RE-PLAN CITY LIFE project.

Why is this profitable method still rare among contractors?

Rubberised asphalt has been demonstrated as technically viable and more sustainable through experiences and demonstrations in many countries, confirming their feasibility and benefits. Recycled rubber plays a crucial role in enhancing the performance and durability of road asphalts. It can be incorporated in two primary methods: the wet method, involving adding powdered recycled rubber to hot bitumen, and the dry method, where rubber granulate is directly mixed with aggregates. The specific approach chosen depends on the process and mix design, allowing for the optimization of various performance aspects. The first documented application of this technique dates back to the 1950s in the United States. This pioneering method has continued to gain momentum due to its significant success in enhancing performance. In contrast, Europe has slowly embraced these innovations and moved beyond demonstration projects. Nevertheless, initial efforts to introduce this technology in the 1980s have played a pivotal role in raising awareness and cultivating technical expertise in various European countries.

Collaborating with RECYKL

Despite the promising potential of these applications, they have not yet gained widespread implementation as they should, mainly due to persistent resistance and various obstacles. RE-PLAN CITY LIFE conducted an analysis to identify the main obstacles to using Recycled Tyre Materials (RTMs) in Roads and Transport Infrastructures as well as solutions to be promoted and implemented through the project. We described them in detail, clearly showing the current situation and future scenarios. The presentation also included recent innovation developments by the company RECYKL about using recycled textile in road applications in Poland.

For the first time, waste textile resulting from tire recycling has transformed into a professional-grade product for road construction as a stabilizer and dispersed reinforcing additive. This development marks the completion of the ELT recycling cycle, enabling nearly 100% tyre recycling. Large-scale production has started in Chełm, Poland, with support from the Engineering Procurement Contracting and Commissioning (EPCC) company Zeppelin. Any player worldwide has the opportunity to establish such a factory and provide standardized products to road construction companies. The product enhances resistance to rutting, fatigue, and cracking, as well as water and temperature effects. During the event, the poster session was held, where Ir. Zaprzalski from RECYKL elaborated on the advantages of incorporating textiles in road construction.

In this context, the diverse opportunities and innovations already developed and tried within the sector were observed. However, these advancements often appear fresh and unverified because of limited information and networking among key market participants. RE-PLAN CITY LIFE is committed to breaking this cycle by disseminating valuable insights and increased awareness about recycled tyre materials.

SUSTAINABLE SOLUTIONS WITH RECYCLED MATERIALS AT THE BUILDING EXHIBITION “SAIE” IN BARI

SAIE is the Italian exhibition that represents the largest community of companies, professionals and associations in the construction sector. This year SAIE recorded the highest numbers ever: 407 companies on display , +64% compared to 2021, and 25,527 visiting professionals (+35%).

SAIE is a strong commercial multiplier for the market, a moment of reflection and comparison for the sector and the reference appointment with the operators of the sector to discover the excellence of the entire construction supply chain, through paths dedicated to the key themes of sustainability, innovation, energy efficiency and digital transformation. The event garnered significant attention with 123 training conferences and 25 special initiatives, as well as the support of 75 trade associations.

In this context, ETRA, in collaboration with ANTEL, organized the workshop: “Circular Economy in Construction for environmental sustainability, research, strategies, innovations and experiences on the reuse of recycled materials”. This national event addressed technicians of both the private and public sector.

The presentations were focused on building application of Recycled Tyre Materials (RTMs), spanning from rubber, steel, and textile ion concrete to thermal and noise insulating products and applications done with the rubber and textile. Also Urban and Sports applications were described as the Fair attracts a really wide spectrum of interests. The workshop was supported by some speakers and partners from the RE-PLAN CITY project.

One of the topics covered during the session was: The use of RTMs in cement-based mortars and in the precast concrete industry. In particular, it was also discussed how to manage new cement-based composites. Prof. Alessandro Fantilli from Politecnico of Turin (partner of Replan) provided insights into the process and revealed valuable findings, such as the increase in strength reduction factor with presence of recycled carbon fibers.

Prof. Dora Foti shared knowledge on the topic of Innovative and eco-sustainable concrete produced from the reuse of waste materials for circular construction. It addressed the challenges, explained also by Fantilli, of the depletion of natural aggregates and need to find replacement. She worked on plastic recycling, with a specific focus on Polyethylene Terephthalate (PET). An Experimental Campaign was conducted to discover best practices for incorporation PET recycled materials into construction products. The tests showed that the inclusion of PET fibers in concrete enhances its ductility. Moreover, PET bars can be employed as alternatives to welded or reinforcing steel links in conditions with high humidity and steel corrosion issues.

Prof Bruno Marabotto revealed the topic of the use of recycled rubber in sports facilities and artificial grass fields, potential and contradictions, which is a common concern. Dr. Ettore Musacchi continued the discussion with another promising application: panels for thermo-acoustic insulation with recycled textile fibers. The growing need for isolation presents new challenges, and using recycled textile fibers from tyres is one of the solutions. Various products and their technical characteristics were described, along with applications of rubber mortar for these purposes, accompanied by examples and works carried out.

This enlightening session provided a platform for specialists and manufacturers in the industry to not only share valuable knowledge but also to discuss practical experiments, tests, and working solutions while considering all the associated advantages and challenges.

Among the speakers there was also Dr. Sergio Saporetti, an Officer of the Italian Ministry of the Environment committed to the preparation of the Green Public Procurement for the building sector. They analyzed the mandatory criteria and contractual clauses of the Minimum Environmental Criteria for constructions.

The workshops allowed a lively interaction among speakers and participants who shared their experience and willingness to cooperate on expanding best practices. The RE-PLAN CITY project was also presented, as it combines many discussed topics revealed at SAIE and aims to use recycled tyre materials in diverse areas of the city's infrastructure.

More information about the event: https://www.saiebari.it/en/

©