©

NEWS FROM RE-PLAN CITY LIFE

WHAT’S NEW

ECONOMIC & ENVIRONMENTAL BENEFITS

PUBLIC ADMINISTRATION ENGAGEMENT - POLL

TYRE RECYCLING PROJECT AT THE REUSE ECONOMY EXPO

Why is rubberized asphalt a game-changer? Lower costs, less noise, and longer-lasting roads. Learn how it benefits both the economy and the environment!

We conducted a survey "Has your administration ever used rubberized asphalt in road construction?" and are ready to share the results with you!

The event serves as a meeting point for multisectoral actors united by a common goal: making reuse an economic and environmental opportunity.

ROADS MORE DURABLE, SAFER AND QUIETER WITH ASPHALT MADE WITH RECYCLED RUBBER

INTERVIEW TO THE PRESIDENT OF ETRA, ETTORE MUSACCHI

What does the Re-Plan City Life project is about?

Re-Plan is a Life project, which aims to raise awareness and increase knowledge among Technicians, Public Administration and Stakeholders in a broad sense on the use of materials deriving from tyre recycling. These are materials that are widely used in public works in the fields of roads, railway infrastructure, construction, sports facilities, street furniture, etc. and therefore potentially on a very large market. Often there is no awareness of the techniques and materials and therefore the project aims to increase this knowledge and involve these actors, with a series of activities that are the heart of the project itself.

Adopting eco-friendly behaviors and practices in urban communities is one of the goals of your association. What is the current picture?

It is a chiaroscuro photograph: there are public administrations that are extremely motivated, there are extremely sensitive and prepared technicians, and others that are very far from this logic; it is difficult to make an average.

How important is the contribution of recycled rubber asphalt in terms of environmental impact?

There are ships with impressive quantities of EOL tyres that leave Europe for destinations in countries with less economic development and less environmental control whose final destination is not always so sustainable. The main contribute consist in recycle them in the EU in a sustainable way. Another benefit is the quality of what you get from tyre recycling, and the better performance you obtain by using these materials. These are materials that often replace virgin materials and this substitution obviously occurs if there is a combination of economic convenience and performance.

What is the contribution of recycled rubber asphalt in the case of roads?

In the case of roads, this technique began in the United States in the 1950s, while in Europe there are many experiments and tests: in Europe, it is understood and known that it can work, but it is not possible to make it a systematic and organic use. In terms of public works, the benefit is more durable, safer, and quieter roads. Depending on the mix design of the road, certain performances can be emphasized or others. The other virtuous aspect is that the use of rubber powder occurs through companies or by subjects who have an openness to improve or increase the overall quantities of recycled material in the roads, therefore not only the rubber but also the quantity of milled material or recycled aggregates, and more ecological additives. In conclusion, there is a whole logic that accompanies the use of powder that would certainly make the infrastructure better.

(Excerpt from the LIFE SILENT newsletter n. 12 dated 26th February 2025)

IS THE INFILL BAN THE SCAPEGOAT TO DIVERT ATTENTION FROM MOST DANGEROUS MICROPLASTICS?

On the 26thApril 2023 the EU member states voted to support a revised REACH Restriction proposal on intentionally added microplastics, which includes a ban of recycled rubber infill materials used in synthetic turf surfaces after a transition period of eight years, before the placing on the market of polymeric infill materials become prohibited.

The ban makes no sense, as it increases the releases of rubber crumbs from turfs instead of reducing it over the next 20 years and does not stimulate a more responsible management and use of Artificial pitches.

Furthermore the decision does not address the problem of other releases of microplastics actually micro and spread in environment in huge quantities:

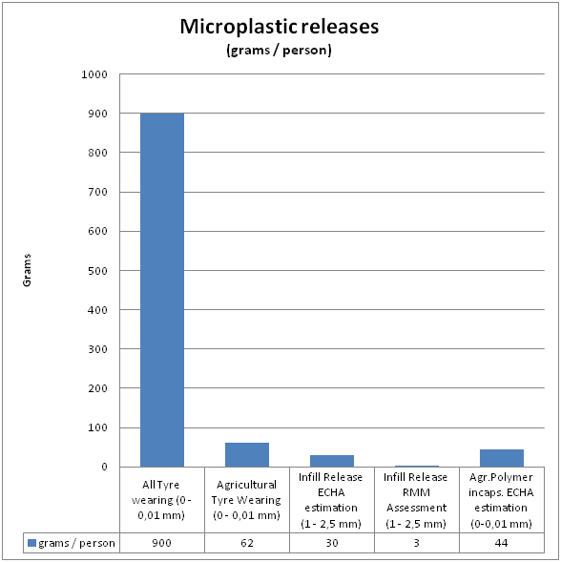

Ø The main source of micro-plastics from tyres is represented by the tyre wearing particles, which are more impacting either for the quantity released or the dimension = 900 g / person (0 – 0,01 mm)

Ø Micro-plastics releases from Artificial turf in comparison are negligible = between 3 and 30 g/ person (1 – 2,5 mm)

Ø Tyre wearing in Agricultural sector is the one more dangerous for the concentration and the direct impact in the fields cultivated for foods crops = 62 g / person (0 – 0,01 mm)

Ø Polymer for seeds and fertilizers incapsulation in Agriculture (ECHA Report) which have also a strong concentration and direct impact in the crops fields = 44 g / person (0 – 0.01)

As there are no benefits deriving from the ban of rubber infill for the environment, nor for the recyclers, as well as for citizens and players, the question arises spontaneously: who will benefit from it ?

DO WE NEED ROBOTS TO RESTORE COMMON SENSE?

How A.I. think that micro-plastics issues should be handled.

Who are you?

I am a highly intelligent question answering bot. If you ask me a question that is rooted in truth, I will give you the answer. If you ask me a question that is nonsense, trickery, or has no clear answer, I will respond with "Unknown".

What is your opinion on Microplastics ?

… see the full interview in the attachment or through this link:

https://www.linkedin.com/pulse/do-robots-play-football-how-ai-think-micro-plastic-issues-

The recycled rubber infill material is again under threaten owing to the Microplastics issue which could lead to a ban of the use of rubber granulate infill material, creating major problems to turf sector and compromising the whole tyre recycling value chain.

The Working Group on Sport of RE-PLAN CITY LIFE has been working on this topic to counter the ban, making evident that it would be useless and counterproductive, instead supporting the adoption of containment measures and a responsible use of artificial turf.

RE-PLAN CITY LIFE Working Group will meet you in Brussels on 29th March 2023 during the ETRA Conference to propose others and more sophisticated method of analysis and discuss further together the possible solutions to adopt.

More info here: https://etra-eu.org/events/item/145-28th-etra-conference-on-tyre-recycling

©